Thread Starter

#31

Re: Enfield Bullet Tacho signal Options

Even I was thinking of a digital speedo setup on my Vijai Super. Check the links below.

http://beedspeed.com/lambretta-speedometer-revstemp-sipkoso-black-p-10154.html

Acewell - Acewell Speedometers - ACE-2xxx - ACE-RLx Lambretta GP and Series 3 adaptor | Digi dash | Digital Speedomter | Motorcycle Computer

The SIP Speedo is a complete unit with tacho, speed, trip, & engine temperature. But it is as expensive as the scooter itself. So added this in my wish list and wait till either the price of the speedo drops down or my scooter appreciates more such that the speed's price becomes justifiable.

The copper wire in the alternator is really thick that it can carry a few amperes of current without any struggle. There was no calculation behind choosing the 27 guage. Went through a wire shop, scanned around for the wires he had and picked one which I could wind myself without much trouble.

And about the number of turns, some internet search on DIY coil winding, I got to know that a stator of the size of Bullet's with 44 turns can make 20V at idle and 40V at some 4000 rpm. So I made 40 turns per pole as a rough number. Still to protect the tacho & BCU, this AC signal will be routed through a Bajaj Chetak AC regulator which can control and deliver only 12V AC. So no risk of overvoltage as the engine revs up.

I was seriously considering an Acewell Speedometer which is a thing of beauty but , too expensive.

When selecting a 27 gauge copper wire, did you try & match the gauge of wire in the existing coil ? And how many windings are necessary? I haven't checked my coil yet and hope to during the tacho installation.

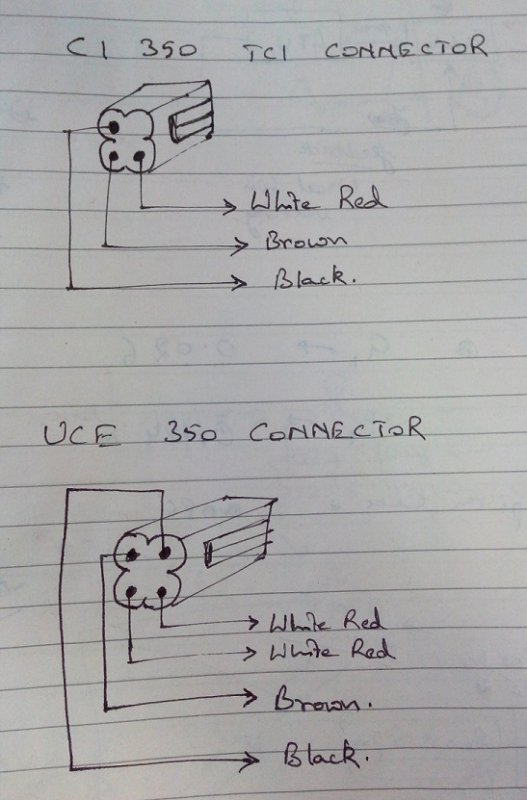

Who knows, I am so excited about your progress that once you are done, I am inclined to copy whatever you 're doing to my UCE electra (if it doesnt spoil the looks of course)

When selecting a 27 gauge copper wire, did you try & match the gauge of wire in the existing coil ? And how many windings are necessary? I haven't checked my coil yet and hope to during the tacho installation.

Who knows, I am so excited about your progress that once you are done, I am inclined to copy whatever you 're doing to my UCE electra (if it doesnt spoil the looks of course)

http://beedspeed.com/lambretta-speedometer-revstemp-sipkoso-black-p-10154.html

Acewell - Acewell Speedometers - ACE-2xxx - ACE-RLx Lambretta GP and Series 3 adaptor | Digi dash | Digital Speedomter | Motorcycle Computer

The SIP Speedo is a complete unit with tacho, speed, trip, & engine temperature. But it is as expensive as the scooter itself. So added this in my wish list and wait till either the price of the speedo drops down or my scooter appreciates more such that the speed's price becomes justifiable.

The copper wire in the alternator is really thick that it can carry a few amperes of current without any struggle. There was no calculation behind choosing the 27 guage. Went through a wire shop, scanned around for the wires he had and picked one which I could wind myself without much trouble.

And about the number of turns, some internet search on DIY coil winding, I got to know that a stator of the size of Bullet's with 44 turns can make 20V at idle and 40V at some 4000 rpm. So I made 40 turns per pole as a rough number. Still to protect the tacho & BCU, this AC signal will be routed through a Bajaj Chetak AC regulator which can control and deliver only 12V AC. So no risk of overvoltage as the engine revs up.

Last edited:

![Guns [gun] [gun]](https://www.theautomotiveindia.com/forums/images/smilies/Guns.gif)

.

.![Smile [:)] [:)]](https://www.theautomotiveindia.com/forums/images/smilies/Smile.gif)

![Clap [clap] [clap]](https://www.theautomotiveindia.com/forums/images/smilies/Clap.gif)