Thread Starter

#1

Maharashtra Chief Minister Shri Devendra Fadnavis formally hands over 25 ‘Tata Starbus Hybrid Electric Bus’ from Tata Motors to MMRDA

The launch ceremony was presided by Shri Anant Geete, Union Minister Heavy Industry and Public Sector Enterprises

Hon’ble Chief Minister of Maharashtra, Shri Devendra Fadnavis inaugurating the new Tata Starbus Hybrid Electric Bus delivered to MMRDA by Tata Motors

Mr. Girish Wagh, President - CVBU, Tata Motors handing over the Tata Starbus Hybrid Electric Bus to Hon’ble Union Cabinet Minister for Heavy Industries and Public Sector Enterprises – Shri Anant Geete, Shri Devendra Fadnavis Hon’ble Chief Minister of Maharashtra in the presence of Shri. Urvinder Pal Singh Madan, IAS, Metropolitan Commissioner, MMRDA

The launch ceremony was presided by Shri Anant Geete, Union Minister Heavy Industry and Public Sector Enterprises

Hon’ble Chief Minister of Maharashtra, Shri Devendra Fadnavis inaugurating the new Tata Starbus Hybrid Electric Bus delivered to MMRDA by Tata Motors

Mr. Girish Wagh, President - CVBU, Tata Motors handing over the Tata Starbus Hybrid Electric Bus to Hon’ble Union Cabinet Minister for Heavy Industries and Public Sector Enterprises – Shri Anant Geete, Shri Devendra Fadnavis Hon’ble Chief Minister of Maharashtra in the presence of Shri. Urvinder Pal Singh Madan, IAS, Metropolitan Commissioner, MMRDA

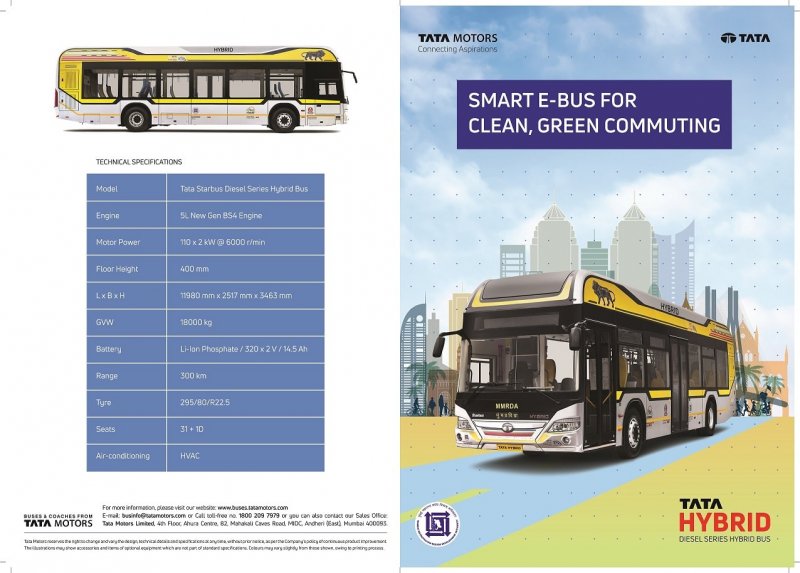

Key Highlights:

First Indian manufacturer to commercially deploy Series Hybrid technology in India

Chassis with new generation BS IV Engine

All new stylized body design

First in the industry: Full Low floor bus Configuration

Enhanced NVH system

Most Advanced Lithium Ion batteries in Automotive Industry (Prismatic Cell)

Tata Motors Proprietary New Generation Telematics system for remote diagnostic

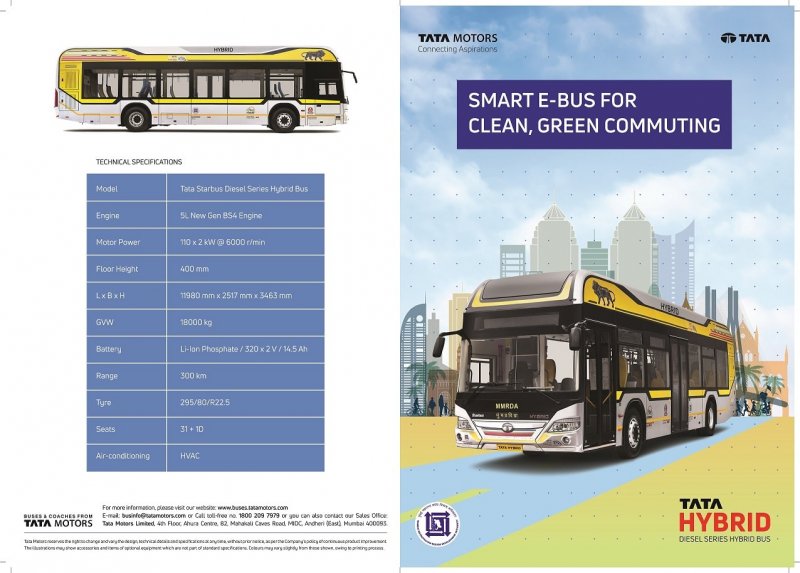

Mumbai, March 16, 2018: Tata Starbus Hybrid Electric Bus with Full Low Floor configuration from Tata Morors’ was today formally handed over to MMRDA at the launch ceremony in Mumbai today. Developed indigenously, the Tata Starbus Series Hybrid bus comes with global design standards and looks stylish with a premium and robust road presence. The Tata Starbus Hybrid Electric Bus runs on dual power, i.e. diesel and electric and is economically viable, safe and environmentally friendly. It comes loaded with class-leading comfort and safety features for passengers. It is the future of rapid urban mass transportation system. The vehicle also complies with all UBS-II (Urban Bus Specifications), AIS 052 (Automotive Industry Standards) and CMVR (Central Motor Vehicle Rules). Mumbaikars can experience the first ‘Made in India’ Hybrid Buses on the Bandra Kurla Complex route in the city.

Commenting on this milestone, Mr. Girish Wagh, President, Commercial Vehicles Business, Tata Motors said, “With sustainability at the heart of our innovation programme, we at Tata Motors, have led technology changes in the Indian commercial vehicle industry over the last six decades. The Tata Starbus Hybrid Electric is India’s First Series Hybrid Electric Architecture Bus and is a testimony to our technology prowess and deep understanding of our customer requirements. We are committed to developing low-emission buses that make substantial contribution towards sustainable urban transport. We will continue our work on electrification and alternate fuel technologies and engage with the government and regulatory authorities to promote these smart technologies and develop products further strengthening the future of Green Mobility in India.”

Dr. AK Jindal, Head Engineering (Electric and Defence) CVBU, Tata Motors said, “Tata Motors is the country’s largest bus manufacturer, with a complete range of transit vehicles that meets every need, arising from day-to-day travel. The company continues to be a leader in the segment not just by setting technological benchmarks but by also adapting innovations effectively to suit Indian travel conditions. With an entire range of coach designs, e.g. microbus, intercity and touring coaches, luxurious inter-city travel options, to safe transport choices for school going children, Tata Motors is best suited to cater to customers’ needs with an entire gamut of day-to-day mass passenger transport solutions.”

Tata Motors is India’s No 1 Bus brand and it is constantly evolving with needs of its customers. The Starbus Hybrid Electric Bus is step towards providing State Transport Undertakings (STUs) a Smart Public Transport Solution with class-leading and greener technology and best-in-class comfort and safety features for passengers.

About Tata Motors

Tata Motors Limited, a USD 42 billion organisation, is a leading global automobile manufacturer of cars, utility vehicles, buses, trucks and defence vehicles. As India’s largest automobile company and part of the USD 100 billion Tata group, Tata Motors has operations in the UK, South Korea, Thailand, South Africa, and Indonesia through a strong global network of 76 subsidiary and associate companies, including Jaguar Land Rover in the UK and Tata Daewoo in South Korea. In India, Tata Motors has an industrial joint venture with Fiat. Engaged in engineering and automotive solutions, with a focus on future-readiness and a pipeline of tech-enabled products, Tata Motors is India’s market leader in commercial vehicles and among the top in passenger vehicles with 9 million vehicles on Indian roads. The company’s innovation efforts are focused on developing auto technologies that are sustainable as well as suited. With design and R&D centres located in India, the UK, Italy and Korea, Tata Motors strives to pioneer new products that fire the imagination of GenNext customers. Abroad, Tata cars, buses, and trucks are being marketed in Europe, Africa, the Middle East, South Asia, South East Asia, South America, Australia, CIS, and Russia.

Commenting on this milestone, Mr. Girish Wagh, President, Commercial Vehicles Business, Tata Motors said, “With sustainability at the heart of our innovation programme, we at Tata Motors, have led technology changes in the Indian commercial vehicle industry over the last six decades. The Tata Starbus Hybrid Electric is India’s First Series Hybrid Electric Architecture Bus and is a testimony to our technology prowess and deep understanding of our customer requirements. We are committed to developing low-emission buses that make substantial contribution towards sustainable urban transport. We will continue our work on electrification and alternate fuel technologies and engage with the government and regulatory authorities to promote these smart technologies and develop products further strengthening the future of Green Mobility in India.”

Dr. AK Jindal, Head Engineering (Electric and Defence) CVBU, Tata Motors said, “Tata Motors is the country’s largest bus manufacturer, with a complete range of transit vehicles that meets every need, arising from day-to-day travel. The company continues to be a leader in the segment not just by setting technological benchmarks but by also adapting innovations effectively to suit Indian travel conditions. With an entire range of coach designs, e.g. microbus, intercity and touring coaches, luxurious inter-city travel options, to safe transport choices for school going children, Tata Motors is best suited to cater to customers’ needs with an entire gamut of day-to-day mass passenger transport solutions.”

Tata Motors is India’s No 1 Bus brand and it is constantly evolving with needs of its customers. The Starbus Hybrid Electric Bus is step towards providing State Transport Undertakings (STUs) a Smart Public Transport Solution with class-leading and greener technology and best-in-class comfort and safety features for passengers.

About Tata Motors

Tata Motors Limited, a USD 42 billion organisation, is a leading global automobile manufacturer of cars, utility vehicles, buses, trucks and defence vehicles. As India’s largest automobile company and part of the USD 100 billion Tata group, Tata Motors has operations in the UK, South Korea, Thailand, South Africa, and Indonesia through a strong global network of 76 subsidiary and associate companies, including Jaguar Land Rover in the UK and Tata Daewoo in South Korea. In India, Tata Motors has an industrial joint venture with Fiat. Engaged in engineering and automotive solutions, with a focus on future-readiness and a pipeline of tech-enabled products, Tata Motors is India’s market leader in commercial vehicles and among the top in passenger vehicles with 9 million vehicles on Indian roads. The company’s innovation efforts are focused on developing auto technologies that are sustainable as well as suited. With design and R&D centres located in India, the UK, Italy and Korea, Tata Motors strives to pioneer new products that fire the imagination of GenNext customers. Abroad, Tata cars, buses, and trucks are being marketed in Europe, Africa, the Middle East, South Asia, South East Asia, South America, Australia, CIS, and Russia.

Akash

![Roll Eyes [roll] [roll]](https://www.theautomotiveindia.com/forums/images/smilies/Roll.gif)

![Smile [:)] [:)]](https://www.theautomotiveindia.com/forums/images/smilies/Smile.gif)

![Surprise [surprise] [surprise]](https://www.theautomotiveindia.com/forums/images/smilies/Surprise.gif)